Ball Pressure

Ball Pressure Specification

- Automation Grade

- Manual

- Accuracy

- Precision machined

- Dimension (L*W*H)

- 170 mm x 150 mm x 240 mm

- Treatment Type

- Thermal Testing

- Humidity Range

- Power

- Product Type

- Ball Pressure Apparatus

- Suitable For

- Testing plastic insulating and sheathing materials

- Storage Capacity

- Use

- For laboratory and industrial test standards

- Phase

- Single Phase

- Frequency

- Height

- 240 mm (overall)

- Temperature Range

- Up to 200C (as per testing standards)

- Display Type

- Material

- Stainless Steel and Brass

- Weight

- 3 kg

- Function

- Measures ball indentation after thermal exposure

- Color Code

- Silver & Brass

- Application

- Testing the effect of heat on hard/soft plastic parts

- Shape

- Rectangular Base with hemispherical indenter

- Display

- No display

- Power Source

- Manual

- Voltage

Ball Pressure Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- Unit

- Delivery Time

- 1 Months

- Packaging Details

- Paid Packaging

- Main Export Market(s)

- Western Europe, Africa, Central America, Eastern Europe, Middle East, South America, Asia, North America, Australia

- Main Domestic Market

- All India

About Ball Pressure

Cashing in on our experience gained since 1988, we are excelling in the domain of manufacturing, supplying and exporting Ball Pressure. These are commonly used in power generation, chemical, paper & pulp industries for controlling emission of steam. All products are manufactured under the directions of experienced professionals employing advanced technology and techniques. To meet the variegated requirements of clients, Ball Pressure is offered in customized configurations.

Features:

- Resistant to corrosion

- Easy to install

- Accurate dimensions

- Resistant to heat

Additional information:

We offer a wide range of Ball Pressure that is made in the state of the art facilities under the strict supervision of our skilled engineers. They can also be customized as per client specifications. These valves are specially developed to meet the industry requirement of a safe and reliable shut off valve applications. Our range of ball valves is designed for superior emission control and has documented high performance level without stem leakage. These are fabricated using quality raw material. Moreover, these valves are widely acclaimed for optimum performance and durability. Our range is mainly used in the high temperature fields like power generation, chemical, paper and pulp industries.

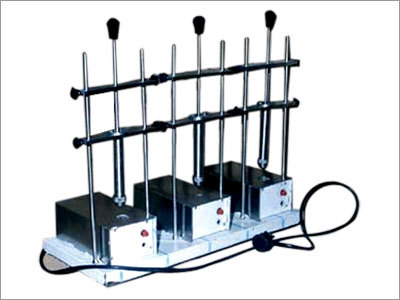

Precision Testing for Plastics

Engineered for both laboratory and industrial use, this apparatus delivers meticulous results when assessing thermal deformation in plastic insulating and sheathing materials. The hemispherical indenter and bright stainless steel base combine for repeatable measurements, ensuring standards compliance during every test.

Robust Construction for Reliability

With polished stainless steel and brass components, along with a heavy-duty clamping assembly, the device withstands prolonged use while maintaining accuracy. The overall dimensions (170 x 150 x 240 mm) and moderate weight (3 kg) make it suitable for benchtop setups, offering stability throughout testing cycles.

Thermally Controlled Indentation Measurement

Designed to accommodate calibrated thermometers, the apparatus enables precise thermal evaluation up to 200C. Operators benefit from straightforward manual processes, allowing for reliable monitoring of material performance under heat stress, per international testing standards.

FAQs of Ball Pressure:

Q: How is the ball pressure test conducted using this apparatus?

A: The test involves positioning the plastic sample on the polished stainless steel base and applying the 5 mm hemispherical indenter with heavy brass weights. The sample is then exposed to controlled heat, with a thermometer monitoring temperatures up to 200C. After heating, the indentation is measured to assess material resistance to thermal deformation.Q: What types of plastics can be tested with this equipment?

A: This apparatus is suitable for insulating and sheathing plastics, both hard and soft variants. It is specifically designed to evaluate materials used in electrical and industrial applications, determining their performance when subjected to elevated temperatures.Q: When should this ball pressure test be performed?

A: The test is typically conducted during material qualification, quality assurance, and research stages. It is crucial whenever plastic components are intended for usage in environments where thermal stability is required, ensuring compliance with laboratory and industry standards.Q: Where is the ball pressure testing apparatus commonly utilized?

A: This device is predominantly used in laboratories and industrial facilities, especially those involved in producing or certifying electrical insulation and sheathing materials. Its manual operation and compact size allow for deployment on benchtops or designated testing areas.Q: What is the process for accommodating the thermometer during testing?

A: A dedicated slot is provided as per standards, enabling secure placement of a thermometer. Operators can closely monitor the temperature conditions within the testing range, from room temperature up to 200C, ensuring precise control throughout the procedures.Q: How does manual operation benefit the testing process?

A: Manual operation offers precise control over each test step and weight application, reducing the risk of mechanical failure and ensuring accuracy. It allows operators to directly manage temperature exposure and mechanical force, which is critical for reliable results.Q: What are the advantages of using this apparatus in thermal testing of plastics?

A: The apparatus delivers high accuracy due to precision machining and the ability to simulate real-world thermal exposure. Its robust construction and compliance with standardized practices ensure repeatable, reliable measurements essential for material development and quality assurance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Hospital Equipments Category

Electrode Oven

Minimum Order Quantity : 1 Unit

Temperature Range : 50C to 300C

Height : 400 mm

Use : Maintaining Electrodes at Preset Temperature

Phase : Single Phase

Power : 2 kW

Rapid Oil Extraction

Minimum Order Quantity : 1 Unit

Temperature Range : Up to 280C

Height : 370 mm

Use : Suitable for commercial and domestic oil extraction

Phase : Single Phase

Power : 600 W

Fully Automatic Water Suspan

Minimum Order Quantity : 1 Unit

Temperature Range : 5C to 50C

Height : 180 mm (approx.)

Use : Industrial and Domestic Water Dispensing

Phase : Single Phase

Power : 70 Watt

Oil Bath

Minimum Order Quantity : 1 Unit

Temperature Range : Room Temperature to 300C

Height : 250 mm (approx)

Use : Precise Thermostatic Heating for Samples

Phase : Single Phase

Power : 1500 Watts

|

GLOBAL CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry