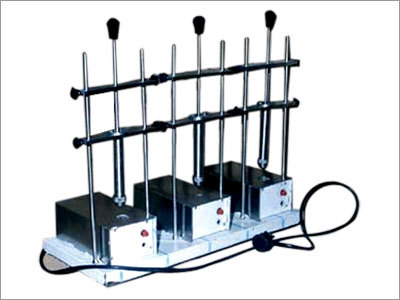

Electrode Oven

Electrode Oven Specification

- Accuracy

- 2C

- Product Type

- Electrode Oven

- Automation Grade

- Manual

- Properties

- Corrosion Resistant Body, Robust Design

- Treatment Type

- Thermal

- Display Type

- Temperature Gauge

- Phase

- Single Phase

- Storage Capacity

- 50 kg

- Frequency

- 50 Hz

- Material

- Mild Steel

- Application

- Storage & Drying of Welding Electrodes

- Temperature Range

- 50C to 300C

- Function

- Drying & Holding Electrodes

- Height

- 400 mm

- Use

- Maintaining Electrodes at Preset Temperature

- Humidity Range

- < 40%

- Shape

- Rectangular

- Dimension (L*W*H)

- 600 x 400 x 400 mm

- Suitable For

- Industrial Welding

- Color Code

- Blue & Grey

- Weight

- 24 kg

- Power

- 2 kW

- Voltage

- 220 V

- Power Source

- Electric

Electrode Oven Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque

- Supply Ability

- Unit

- Delivery Time

- 1 Months

- Packaging Details

- Paid Packaging

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Electrode Oven

Strengthened by technically sound manpower, we are able to manufacture, supply and export Electrode Oven. We make sure that all products are manufactured using only quality assured materials and components that are sourced from authentic vendors of market. In order to supply clients with flawless product, Electrode Oven is thoroughly checked on several predefined quality parameters. Clients can avail from us bulk quantities of the aforesaid product at industry leading prices.

Features:

- Sturdy design

- Easy to maintain

- Low power consumption

- Longer functional life

Corrosion Resistant Construction

Featuring a stainless steel inner chamber and powder-coated mild steel outer body, the electrode oven is built to withstand industrial environments. Its corrosion-resistant structure ensures longevity and reliability, making it suitable for frequent industrial use where moisture and harsh conditions are commonplace.

Precise Temperature Control

The capillary type adjustable thermostat enables accurate setting and maintenance of the desired temperature between 50C and 300C, with an impressive accuracy of 2C. This ensures welding electrodes are properly dried and held at optimal temperature, reducing the risk of moisture contamination and improving weld quality.

Convenient Portability & Design

Engineered for mobility, the oven includes a sturdy handle and compact rectangular design (600 x 400 x 400 mm). This makes it easy to move between workstations or job sites, providing flexibility in industrial environments while retaining high storage capacity for electrodes.

FAQs of Electrode Oven:

Q: How does the glass wool insulation benefit the electrode drying process?

A: Glass wool insulation provides excellent thermal retention, minimizing heat loss and ensuring stable internal temperatures. This consistent environment helps maintain electrode dryness and prevents moisture ingress, protecting weld quality.Q: What is the process for adjusting the drying temperature in this oven?

A: Temperature adjustment is straightforward using the capillary type adjustable thermostat. The desired temperature, ranging from 50C to 300C, can be set on the temperature gauge, allowing users to maintain electrodes at precise conditions suitable for the specific type of welding.Q: When should welding electrodes be stored in the oven?

A: Welding electrodes should be stored in the oven both before use and between welding sessions to maintain optimal dryness. This prevents moisture absorption, which could lead to weld defects such as porosity or cracking.Q: Where can this electrode oven be effectively deployed?

A: The oven is ideal for industrial settings, manufacturing plants, and workshops engaged in welding activities. Its portable design and robust construction make it suitable for use on-site or within factory environments.Q: What are the benefits of the corrosion resistant body and robust design?

A: A corrosion resistant body prolongs the ovens lifespan, while the robust design ensures durability and reliability during long-term use. These features help protect the electrodes and maintain consistent drying performance, even in demanding atmospheric conditions.Q: How do I use the oven for storing and drying electrodes safely?

A: Open the single hinged door, place the welding electrodes inside (ensuring the rods do not exceed 450 mm in length), set the desired temperature using the thermostat, and monitor conditions via the temperature gauge. Always ensure the oven is connected to a suitable 220 V single phase power source.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Hospital Equipments Category

Fully Automatic Water Suspan

Minimum Order Quantity : 1 Unit

Color Code : Silver

Material : Stainless Steel Body

Weight : Around 5.5 kg

Temperature Range : 5C to 50C

Power : 70 Watt

Ball Pressure

Minimum Order Quantity : 1 Unit

Color Code : Silver & Brass

Material : Stainless Steel and Brass

Weight : 3 kg

Temperature Range : Up to 200C (as per testing standards)

Power :

Rapid Oil Extraction

Minimum Order Quantity : 1 Unit

Color Code : Silver

Material : Stainless Steel

Weight : 14 kg

Temperature Range : Up to 280C

Power : 600 W

Portable Electrode Oven

Minimum Order Quantity : 1 Unit

Color Code : Yellow / Grey

Material : Mild Steel

Weight : 5 Kg

Temperature Range : 50C to 150C

Power : 165W

|

GLOBAL CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry