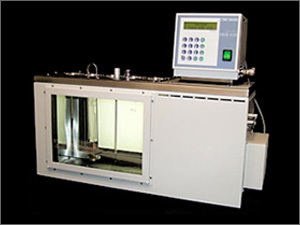

Kinematic Viscosity Bath

Kinematic Viscosity Bath Specification

- Core Components

- Circulation Pump, Digital Controller, Heating Elements

- Measurement Range

- 1 to 2000 mm/s

- Power Source

- Electric

- Accuracy

- 0.1C

- Temperature Range

- Ambient +5C to 100C

- Frequency

- 50 Hz

- Feature

- Uniform Temperature Distribution, Over Temperature Protection

- Automation Grade

- Semi Automatic

- Capacity

- 20 liters

- Voltage

- 230 V AC

- Equipment Materials

- Stainless Steel Inner Chamber with Powder Coated Outer Body

- Type

- Kinematic Viscosity Bath

- Usage

- Industrial, Laboratory, Petroleum and Lubricant Testing

- Display Type

- Digital LED Display

- Dimension (L*W*H)

- 550 x 400 x 500 mm

- Weight

- Approx. 30 kg

Kinematic Viscosity Bath Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- Unit

- Delivery Time

- 1 Months

- Packaging Details

- Paid Packaging

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Kinematic Viscosity Bath

With the help of our technically profound professionals, we are able to manufacture, supply and export Kinematic Viscosity Bath. Integrated with advanced features such as built-in stirrer, digital display to view bath temperature and low bath level protection, our products are widely appreciated among clients. The entire range is rigorously checked at our in-house built testing unit so that any defective product can be removed before the final delivery. Kinematic Viscosity Bath is demanded throughout the world for the below mentioned features:

-

Safe to use

-

Simpler operations

-

Uniform temperature

-

Fast cooling

Additional information:

ASTM D 445 ; IP 71 ; DIN 51562 ; ISO 3104 ; IS-1206 (Part III)-1978.

Highly stable viscosity bath temperatures.

Digital measurement and display.

The Viscosity Bath is designed to simplify ASTM D 445; IS-1206 (Part III)-1978 kinematic viscosity testing. A top-mounted controller keypad permits quick entry of bath set point temperature while a sophisticated microprocessor controls the bath heating and stirring. To further enhance the input, the unit accommodates up to a maximum of six individual capillaries.

The HVB features a measuring range of 5C to 230C and can be used with mineral oil, silicone oil, or water as the bath media. Bath temperature is displayed on a bright, easy-to-read digital display. In addition, the unit features a built-in over-temperature circuit and bath liquid level detector to automatically cut heater power in the event of thermal runaway or insufficient bath media.

Features:

-

Accommodates up to six capillary tubes; optional Cannon-Fenske or canon- menin tube holders available

-

Measures kinematic viscosity of petroleum products at temperatures from 20C to 150C, according to ASTM D 445; IP 71 ; DIN 51562 ; ISO 3104 ; IS-1206 (Part III)-1978

-

Controls bath temperature with 0.01C stability

-

Digital bath temperature measurement and display

-

Large capacity bath with built-in stirrer, optional illumination

-

Integral over-temperature and low bath level protection

The unit has a double walled construction with outer GI /MS powder coat finish & argon welded inner of SS 304, having glass wool insulation between the walls. A motor with stirrer is provided for better temperature uniformity. Toughened glass window from both sides with fluorescent tube for easy visualization. The SS immersion heater does the heating. Digital temperature controller cum indicator controls the process. Cooling of bath is achieved by sealed CFC free compressor & direct copper tubing inside the inner area for fast & accurate cooling.

| Internal dimensions(LxWxD) | Capacity | Ltrs. |

| Heating: | ||

| 1. 25x20x30 cms for 5C above ambient to 230 C. | 4VM | 12 Ltrs. |

| 2. 35x20x30 cms for 5C above ambient to 230C | 6VM | 18 Ltrs. |

| Cooling: | ||

| 3. 25x20x30 cms for 5C to 95C | 4VM | 12 Ltrs. |

| 4. 35x20x30 cms for 5C to 95C | 6VM | 18 Ltrs. |

Simultaneous Multi-Sample Testing

With four adjustable viscometer positions, the bath allows simultaneous testing of multiple samples, drastically increasing efficiency for laboratories and industrial quality control. The precise position locking mechanism ensures stable measurement for each viscometer or capillary tube, even during extended testing cycles.

Superior Temperature Control and Safety

A digital PID microprocessor controller maintains strict temperature uniformity from ambient +5C to 100C, achieving 0.1C accuracy. Premium safety features, such as automatic overheating shutdown and low fluid level alerts, protect both users and samples. The insulated, removable lid further conserves heat and energy.

Industrial-Grade Construction and Easy Operation

Crafted with a stainless steel inner chamber and powder-coated exterior, the bath withstands harsh environments and frequent use. Its intuitive digital LED display provides clear temperature readings, while essential components like the circulation pump, controller, and corrosion-resistant heating element guarantee consistent performance and ease of maintenance.

FAQs of Kinematic Viscosity Bath:

Q: How is the kinematic viscosity measured using this bath?

A: Samples are placed into viscometers, which are held in the bath at set test positions. The microprocessor-controlled system maintains the required temperature, and the time it takes for fluid to flow between calibration marks is recorded. This process determines the kinematic viscosity in compliance with ASTM D445 and D446 standards.Q: What are the primary benefits of the four test positions in the bath?

A: Having four adjustable test positions enables simultaneous analysis of multiple samples, significantly saving time and improving productivity in laboratories and industrial applications. This multi-sample capability is ideal for environments where rapid, batch testing is critical.Q: When should I use water versus another bath fluid?

A: Use water as the bath fluid for temperatures up to around 80C, as it ensures safety and effective thermal transfer. For temperatures above this or for specific samples, use a suitable liquid medium compatible with the operating range (up to 100C) to maintain temperature stability and equipment safety.Q: Where is this kinematic viscosity bath best suited for use?

A: This equipment is designed for industrial laboratories, research centers, petroleum refineries, and lubricant testing facilities. Its robust construction and adherence to ASTM standards make it suitable for intensive and routine testing environments.Q: What safety features are incorporated into the bath?

A: The bath includes over-temperature protection that automatically shuts down heating elements if an unsafe temperature is detected, along with a low fluid level sensor to prevent dry running and potential damage to internal components.Q: How does the circulation pump enhance measurement accuracy?

A: The built-in circulation pump ensures uniform temperature distribution throughout the bath, eliminating hot or cold spots and maintaining precise test conditions for all samples, thus improving the reliability of viscosity measurements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Scientific Laboratory Instruments Category

Humidity Controlled Oven

Minimum Order Quantity : 1 Unit

Equipment Materials : Stainless Steel (Inner), Powder Coated Mild Steel (Outer)

Capacity : 60 Liters

Accuracy : 1C

Power Source : Electric

Frequency : 50 Hz

Automatic Vertical Autoclave

Minimum Order Quantity : 1 Unit

Equipment Materials : Stainless Steel (Grade 304)

Capacity : 50 Liters

Accuracy : 1C

Power Source : Electric

Frequency : 50/60 Hz

Laboratory Muffle Furnace

Minimum Order Quantity : 1 Unit

Equipment Materials : Mild Steel body with ceramic fiber insulation

Capacity : 4 Litres

Accuracy : 5C

Power Source : Electric

Frequency : 50 Hz

Reciprocating Water Bath

Minimum Order Quantity : 1 Unit

Equipment Materials : Stainless Steel (inner chamber), Powder coated MS (outer body)

Capacity : 12 liters

Accuracy : 0.5C

Power Source : Electric (230V AC)

Frequency : 50 Hz

|

GLOBAL CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry