Laboratory Muffle Furnace

Laboratory Muffle Furnace Specification

- Power Source

- Electric

- Temperature Range

- Ambient to 1200C

- Core Components

- Heating Elements, Ceramic Chamber, Digital Controller

- Measurement Range

- 0C to 1200C

- Capacity

- 4 Litres

- Accuracy

- 5C

- Feature

- High insulation, Fast heating, Durable construction

- Voltage

- 230V AC

- Frequency

- 50 Hz

- Equipment Materials

- Mild Steel body with ceramic fiber insulation

- Usage

- Laboratory heating and ashing

- Display Type

- Digital

- Dimension (L*W*H)

- 300 x 250 x 250 mm

- Weight

- Approx. 45 kg

Laboratory Muffle Furnace Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- Unit

- Delivery Time

- 1 Months

- Packaging Details

- Paid Packaging

- Main Export Market(s)

- Australia, Middle East, Eastern Europe, North America, Western Europe, Africa, Central America, South America, Asia

- Main Domestic Market

- All India

About Laboratory Muffle Furnace

Leveraging on the expertise of more than 2 decades, we have been specialized in manufacturing, supplying and exporting Laboratory Muffle Furnace. These serve the purpose of quenching, annealing, soldering and other heat treatments in different industries along with scientific research laboratories. In order to rule out possibility of any defect, these are manufactured under the strict supervision of experienced professionals. Integrated with latest features, Laboratory Muffle Furnace is highly demanded in the market for the below mentioned features:

-

Rigid construction

-

Simpler operations

-

Longer functional life

-

Low maintenance

Additional information:

GMP-GC-16 Muffle Furnace of up to 1200°C:

Laboratory muffle Furnace of Max temp: 1200 °C. Working temp: 1150 ºC.

Construction: The unit has an outer body made up of MS with epoxy powder coat finish & a door with a heat resistant handle.

The unit has a double decker type construction with the muffles body at top & the control box at bottom with 1"solid spacer in between. A coil type Heater of Nichrome wire wound on the muffle with cerewool blanket serves as the heating element. A brick insulation of 4" is also given to have skin temp. of furnace less than 50°C. The door is provided with heavy-duty hinges and latch-catchlock system to open/close the furnace.

Control panel: It is located at the base of furnace and includes a controller and stand by solid-state fuse with Cr/Al Thermocouple. Microprocessor based temperature controller cum indicator controls heating process.

| Muffle Size | Rating Kw | |

| 1. | 9x4x4 | 2.0 |

| 2. | 10x5x5 | 2.5 |

| 3. | 12x6x6 | 3.5 |

| 4. | 18x9x9 | 6.5 |

Fast and Precise Heating

Achieve rapid heat-up rates from 10 to 20C per minute with precision control using the PID digital temperature controller. This ensures consistent performance, optimal for laboratory heating, ashing, and material analysis processes.

Durable and High Efficiency Design

Constructed with a mild steel body and 75 mm thick ceramic fiber insulation, the muffle furnace offers excellent heat retention, durability, and operational cost savings. Its compact 4-litre ceramic chamber holds samples securely during thermal cycles.

User-Friendly Digital Control

A digital display and advanced controller simplify temperature programming, monitoring, and adjustment. Operators benefit from clear visualization of measurements ranging from ambient to 1200C with an accuracy of 5C.

FAQs of Laboratory Muffle Furnace:

Q: How does the PID digital temperature controller enhance furnace operation?

A: The PID digital temperature controller ensures precise regulation of chamber temperature, minimizes overshoot, and maintains a stable setpoint. This accuracy (5C) is essential for reliable laboratory heating and ashing processes.Q: What is the benefit of Kanthal wire heating elements in this muffle furnace?

A: Kanthal wire heating elements provide rapid heating rates (10-20C/min), excellent durability, and consistent thermal distribution. This leads to efficient sample processing and reduces operational downtime.Q: What materials are used in the construction of this muffle furnace?

A: The furnace is engineered with a mild steel exterior and ceramic fiber insulation, offering both strength and high thermal efficiency. The ceramic chamber ensures safe containment for samples during heating cycles.Q: Where can this laboratory muffle furnace be installed?

A: It is designed for laboratory environments with ambient temperatures up to 40C. Ideal settings include research institutions, chemical labs, and material testing facilities that require controlled heating and ashing operations.Q: What is the recommended process for using the muffle furnace for ashing samples?

A: Place the samples in ceramic crucibles within the chamber, select the desired temperature (up to 1200C) using the digital controller, and monitor progress on the display. Ensure the furnace is operated in accordance with safety guidelines.Q: When should maintenance be performed for optimal furnace performance?

A: Regular inspection of heating elements, cleaning of ceramic chamber, and verification of controller calibration are recommended every 6 to 12 months or as dictated by usage intensity to sustain efficiency and longevity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Scientific Laboratory Instruments Category

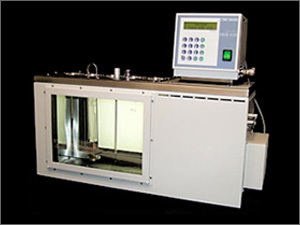

Kinematic Viscosity Bath

Minimum Order Quantity : 1 Unit

Dimension (L*W*H) : 550 x 400 x 500 mm

Weight : Approx. 30 kg

Accuracy : 0.1C

Type : Kinematic Viscosity Bath

Display Type : Digital LED Display

Automatic Vertical Autoclave

Minimum Order Quantity : 1 Unit

Dimension (L*W*H) : 500 x 500 x 1100 mm

Weight : Approx. 75 kg

Accuracy : 1C

Type : Automatic Vertical Autoclave

Display Type : Digital

Humidity Controlled Oven

Minimum Order Quantity : 1 Unit

Dimension (L*W*H) : 455 x 410 x 605 mm

Weight : Approx. 45 kg

Accuracy : 1C

Type : Humidity Controlled Oven

Display Type : Digital

Reciprocating Water Bath

Minimum Order Quantity : 1 Unit

Dimension (L*W*H) : 60 x 27 x 15 cm

Weight : Approx 14 kg

Accuracy : 0.5C

Type : Reciprocating Water Bath

Display Type : Digital (LED Display)

|

GLOBAL CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry