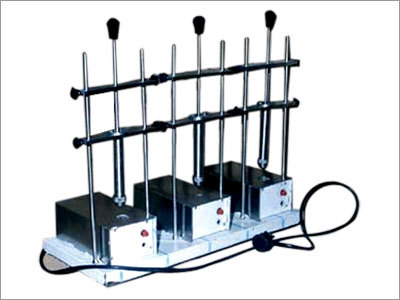

Styrofoam Cutter

Styrofoam Cutter Specification

- Automation Grade

- Manual

- Treatment Type

- Thermal cutting

- Color Code

- Blue and Black

- Material

- Metal and Plastic

- Product Type

- Styrofoam Cutter

- Weight

- Approx. 1.5 kg

- Shape

- Rectangular Base, Curved Handle

- Accuracy

- High cutting accuracy with minimal debris

- Power

- 15W

- Phase

- Single Phase

- Application

- Cutting polystyrene (thermocol), Styrofoam, sponge and soft foam materials

- Properties

- Precise and clean cutting, smooth finish, portable design

- Use

- For crafting, model making, architectural works, insulation fitting and packaging

- Temperature Range

- Up to 350C at cutting wire

- Function

- Heated wire cuts through Styrofoam and similar materials

- Height

- 110 mm (overall height)

- Dimension (L*W*H)

- 350 x 150 x 110 mm

- Power Source

- Electric

- Display

- No display

Styrofoam Cutter Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- Unit

- Delivery Time

- 1 Months

- Packaging Details

- Paid Packaging

- Main Domestic Market

- All India

About Styrofoam Cutter

Owing to our persistent involvement in this domain, we have gained specialization in manufacturing, supplying and exporting Styrofoam Cutter for Oncology. Our products are widely used in cancer treatment process for precise and fast cutting of blocks. The entire range is designed by skilled engineers who incorporated it with advanced features for efficient performance. In order to attain the maximum satisfaction of clients, we assure timely delivery of Styrofoam Cutterfor Oncology at clients' doorsteps.

Features:

- User-friendly

- Low maintenance

- Non-corrosive

- Longer service life

Additional information:

The accurate, easier, fast & profession's choice for cutting Therapeutic shielding forms like writing with fine pen. The styroformer offers the best cost benefit ratio of any available block cutter in the market. Styroformer machine includes verification light, three tracing tips&self locating block holding arms. Basic machine plus hot wire temperature booster & alarm system. The accessories of the cancer treatment radiation process are cold plate, Alloy melter, U.V.source, lead shield trolley. The unique apparatus is basically designed & developed for exposing only those specific area of human body for giving chemotherapy of the human body there by un affected portion is shielded from the hazardous chemotherapic radiation. Thus it is more precise & perfect .The m/c is user friendly & very easy to operate. The unique styroform cutter is indigenously made & constant improvement in its end use makes it more suitable & economical for treatment of cancer effected area. It basically works on the principle of penetrograph m/c where after initial alignment of the m/c the x-ray film of the affected area is kept on a well fluorescent illuminated table. A pointer with a hot 75 mm Nicrom wire is used for cutting, after cutting the cut area can be verified easily for area radiation by verification light of high powered reflected halogen lamp. Where the shadow of the cutting edge matches with that of edge of x-ray film already marked. Various accessories along with styroform cutter like u.v source for illumination of cancerous body for focusing x-ray camera & fluorescent marker pen for marking human body cancerous cell helps in locating defined areas. Low melter alloy consists of perfect % of tin /lead /bismuth /mn/mg etc: cooling plate with silicon matt etc.provides adequate support along with styroform cutter for better treatment of cancer, in oncology department.

Precision and Safety in Every Cut

With its insulated handle, stable rectangular base, and advanced overheat protection, this Styrofoam Cutter is designed to deliver safe, highly accurate cuts. Its temperature-controlled heated wire glides through foam materials, reducing mess and ensuring a consistently smooth finish, making it ideal for both professional and creative projects.

Versatile Usage and Effortless Handling

Perfect for applications such as crafting, architectural model making, insulation fitting, and packaging, this cutter is a reliable tool for professionals and hobbyists alike. Its portable design and manageable weight allow for easy maneuverability, while the included replacement wire and instruction manual ensure hassle-free operation.

FAQs of Styrofoam Cutter:

Q: How does the Styrofoam Cutter achieve precise and clean cuts?

A: The cutter features a 170 mm heated wire that efficiently melts through polystyrene, thermocol, sponge, and similar materials, resulting in high cutting accuracy, minimal debris, and a smooth finish.Q: What safety features are integrated into the Styrofoam Cutter?

A: Safety is ensured with an insulated handle to prevent heat transfer, a stable base for better control, and built-in overheat protection, reducing accident risks during use.Q: When should I replace the cutting wire, and is a replacement included?

A: You should replace the cutting wire when you notice decreased performance or visible wear. A replacement wire is included in the package, and the process is explained in the instruction manual.Q: Where is the Styrofoam Cutter intended to be used?

A: This cutter is designed for indoor environments, making it ideal for studios, workshops, classrooms, and other controlled spaces where precise foam cutting is required.Q: What materials can be cut using this tool, and for what applications?

A: The cutter is suitable for cutting polystyrene (thermocol), Styrofoam, sponge, and soft foam. Common uses include crafting, model making, architectural projects, insulation installations, and packaging tasks.Q: What are the power requirements and operating conditions for this cutter?

A: Operating at 15W, the cutter uses a single-phase electric source and comes with a 1.2-meter cord. It is suitable for typical indoor electrical outlets and manual operation, with a thermal cutting process reaching up to 350C.Q: What are the key benefits of using this Styrofoam Cutter over traditional methods?

A: Compared to manual blades, this cutter offers cleaner, more precise cuts with less debris, enhanced safety due to its insulated design, and smoother finishesall while being portable and easy to operate.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Hospital Equipments Category

Rapid Oil Extraction

Minimum Order Quantity : 1 Unit

Product Type : Oil Extraction Machine

Display Type : LED Display

Treatment Type : Oil Extraction

Temperature Range : Up to 280C

Dimension (L*W*H) : 560 x 230 x 370 mm

Portable Electrode Oven

Minimum Order Quantity : 1 Unit

Product Type : Portable Electrode Oven

Display Type : Dial Gauge

Treatment Type : Electrode Baking

Temperature Range : 50C to 150C

Dimension (L*W*H) : 45 cm x 22 cm x 18 cm

Fully Automatic Water Suspan

Minimum Order Quantity : 1 Unit

Product Type : Fully Automatic Water Suspans

Display Type : LED Digital

Treatment Type : None (Suitable for Clean Water Only)

Temperature Range : 5C to 50C

Dimension (L*W*H) : Approx. 350 x 220 x 180 mm

Electrode Oven

Minimum Order Quantity : 1 Unit

Product Type : Electrode Oven

Display Type : Temperature Gauge

Treatment Type : Thermal

Temperature Range : 50C to 300C

Dimension (L*W*H) : 600 x 400 x 400 mm

|

GLOBAL CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry