Digital Penetrometer

Digital Penetrometer Specification

- Equipment Type

- Digital Penetrometer

- Specimen Size

- Standard Dimensions

- Frequency

- 50 Hz

- Mounting Type

- Table Top

- Max Height

- 300 mm

- Number of Specimens

- 1

- Operating Voltage

- 220V AC

- Port Size

- Standard

- Response Time

- 1 second

- Temperature

- 5C to 40C

- Automation Grade

- Automatic

- Accuracy

- 0.1 units

- Features

- Programmable timer, Auto stop, High precision

- Display Type

- Digital LCD

- Resolution

- 0.1 unit

- Interface Type

- RS232

- Humidity

- 85% RH

- Power Supply

- AC 220V, 50 Hz

- Usage

- Laboratory, Industrial

- Capacity

- 200g

- Machine Weight

- 12 kg

- Test Speed

- 5 mm/s

- Test Width

- 150 mm

- Test Stroke

- 100 mm

- Control Mode

- Digital Control

Digital Penetrometer Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash in Advance (CID), Cheque

- Supply Ability

- Unit

- Delivery Time

- 1 Months

- Packaging Details

- Paid Packaging

- Main Domestic Market

- All India

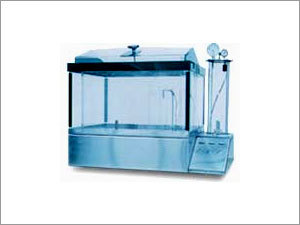

About Digital Penetrometer

Well known for the quality of our products, we have gained a reputable position in the industry as a manufacturer, supplier and exporter of Digital Penetrometer. Designed by experienced professionals, our products are incorporated with advanced features that make it unique as compared to its alternatives. These are commonly used to determine the consistency of different types of materials including food products, lubricating greases, bitumen, creams and pastes. To ensure timely delivery of Digital Penetrometer, it is supplied by reliable carriage and freight personnel.

Applications:

- Cosmetic industry

- Food industry

- Petroleum industry

- Paint industry

Additional information:

- Motorized placement of penetration on sample surface.

- Conforms to all ASTM, IP, ISO 9001 and related specifications

Penetration measurements in the full range of 0-620 in 1/10 mm scale are reported in either 1/10 mm or 1/100 mm increments at the operators option. If a test result falls outside of the programmed range, an audible signal and visual error message alert the user of a failed sample. Results can be communicated to a printer or computer via a built-in RS232 interface.

Illumination with magnifying glass is also provided.

Fine adjustment of the tip of the needle is also provided.

Leveling indicator is also given.

High Precision and Control

Engineered for accuracy, this digital penetrometer provides a resolution of 0.1 unit and is capable of manual and automatic calibration. Easily manage test parameters through digital controls and a user-friendly interface, ensuring repeatable and reliable results every time.

Comprehensive Safety Features

Featuring overload protection and an emergency stop, this device prioritizes operator safety without compromising performance. These built-in safety mechanisms help prevent accidental damage and provide peace of mind during intensive testing sessions.

Designed for Laboratory and Industrial Automation

Built to meet demanding laboratory and industrial standards, this penetrometer supports automatic testing and comes with essential accessories. With RS232 connectivity and programmable functions, it seamlessly integrates into automated test setups.

FAQs of Digital Penetrometer:

Q: How do I calibrate the Digital Penetrometer?

A: Calibration can be performed both manually and automatically using the provided calibration weights. Refer to the user manual for detailed step-by-step instructions on both methods.Q: What environments are suitable for using this digital penetrometer?

A: This device is designed exclusively for indoor use, operating optimally in environments with temperatures between 5C and 40C and relative humidity levels up to 85%.Q: When should I use the overload protection and emergency stop features?

A: Activate the emergency stop if you observe any operational anomalies or require immediate cessation of testing. The built-in overload protection automatically safeguards the device against excessive force during testing.Q: Where can I mount this equipment for reliable operation?

A: The penetrometer is intended for table-top mounting, ensuring stability and accuracy during laboratory or industrial applications.Q: What is the process for switching between probes?

A: To switch probes, simply detach the current stainless steel probe and attach the desired replacement. The interchangeable design allows for quick and secure changes, accommodating different standardized specimen dimensions.Q: What are the benefits of the digital control and automation features?

A: Digital controls and automation provide precise adjustments, programmable timers, auto stop for convenience, and enable integration with automated laboratory workflows via RS232 interface.Q: How can I utilize the included accessories with the machine?

A: Use the carrying case for transport, refer to the user manual for setup and operation guidance, and employ the calibration weights for ensuring testing accuracy before experimental runs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in IS/ASTM Test/Measuring Instruments Category

Louvandro Meter

Minimum Order Quantity : 1 Unit

Specimen Size : 100 mm x 100 mm

Equipment Type : Louvandro Meter

Max Height : 350 mm

Operating Voltage : 220 V

Number of Specimens : 1

Flash & Fire Point Apparatus

Minimum Order Quantity : 1 Unit

Specimen Size : Cup Capacity: 70 ml approx.

Equipment Type : Flash & Fire Point Apparatus

Max Height : Approx. 350 mm

Operating Voltage : 230 V AC

Number of Specimens : Single Specimen/Test

Ductility Apparatus

Minimum Order Quantity : 1 Unit

Specimen Size : 10 mm x 6 mm x 50 mm

Equipment Type : Ductility Measuring Apparatus

Max Height : 160 mm

Operating Voltage : 220 240 V AC

Number of Specimens : 3 specimen slots

Salt Spray Chamber

Minimum Order Quantity : 1 Unit

Specimen Size : Up to 150 70 mm

Equipment Type : Corrosion Testing Chamber

Max Height : 1080 mm

Operating Voltage : 220V AC

Number of Specimens : Up to 40 pieces

|

GLOBAL CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry